Premier Modular, one of the UK’s leading offsite specialists, delivered a £2.6m fast-track project to design and build a new accommodation wing at RAF Coningsby in Lincolnshire. This was Premier’s sixth modular building contract on the base.

The project for BAE Systems, which provides aircraft products and services to the MoD, followed the completion of a new 2,800sqm squadron headquarters at Coningsby.

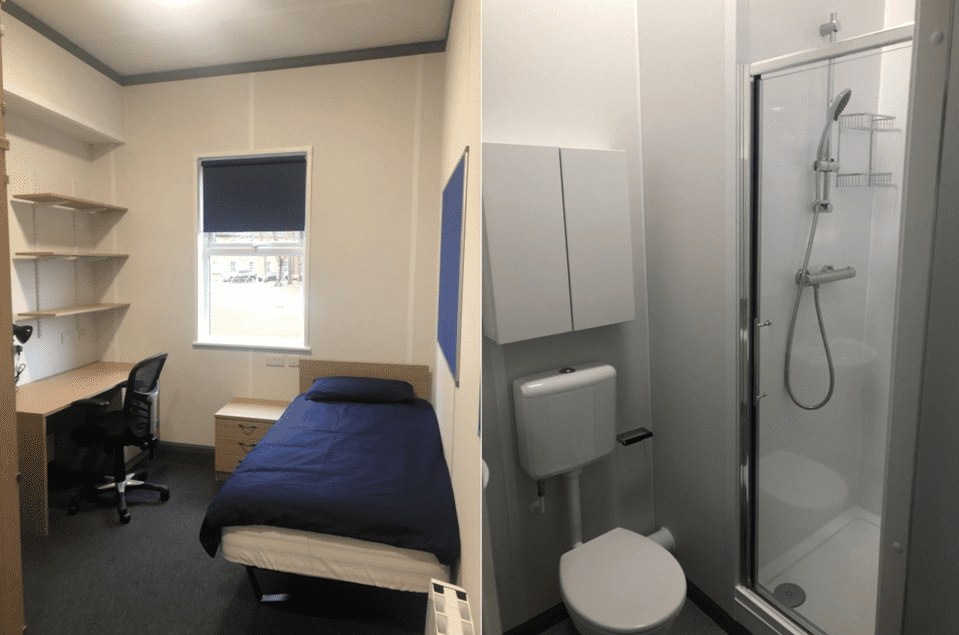

The building provides 66 ensuite bedrooms, communal kitchens, laundry, and bike storage. A separate block was also constructed as part of this contract to accommodate a recreation room, prayer room, and ablution and washing facilities.

RAF Coningsby is home to two frontline, combat-ready squadrons and is the training station for Typhoon pilots, as well as the Battle of Britain Memorial flight. As one of two Quick Reaction Alert Stations, it protects the UK’s southern airspace.

According to the Project Manager at BAE Systems, “Premier Modular performed well on this project and despite the demands of the Covid-19 pandemic, the new facility was completed on time. It was delivered to a high standard throughout and is helping us to meet a requirement for additional accommodation for a period of two years.”

“We appointed Premier following their team’s successful performance on earlier projects for BAE and so had confidence in their ability to deliver. They added value to the scheme, particularly in the design stages with the construction of a prototype bedroom in the factory to allow the client to review finishes and detailing.”

As the accommodation is located on a military site, the building had an enhanced steel structure and toughened glass to the windows to meet security requirements. The installation of the 55 modules was also scheduled for when aircraft were not flying, requiring stringent logistics and planning.

Offsite fitting out was maximised on this project to reduce disruption on site. The modules were pre-fitted with shower rooms, kitchens, partitions, service risers, carpets, fenestration, partitions, and doors. Premier also supplied all fixed and loose furniture and fittings for the turnkey project.

Premier’s offsite building solutions use factory production process to deliver high quality, affordable and sustainable facilities for both temporary and permanent applications, manufactured with zero waste to landfill. There is also much greater certainty of delivery on time and on budget, reduced programme times and significantly less disruption to the customer.

Premier offers a full range of bespoke design, offsite manufacturing, fitting out and construction services to contractors and clients.

Images – courtesy of BAE Systems