Project

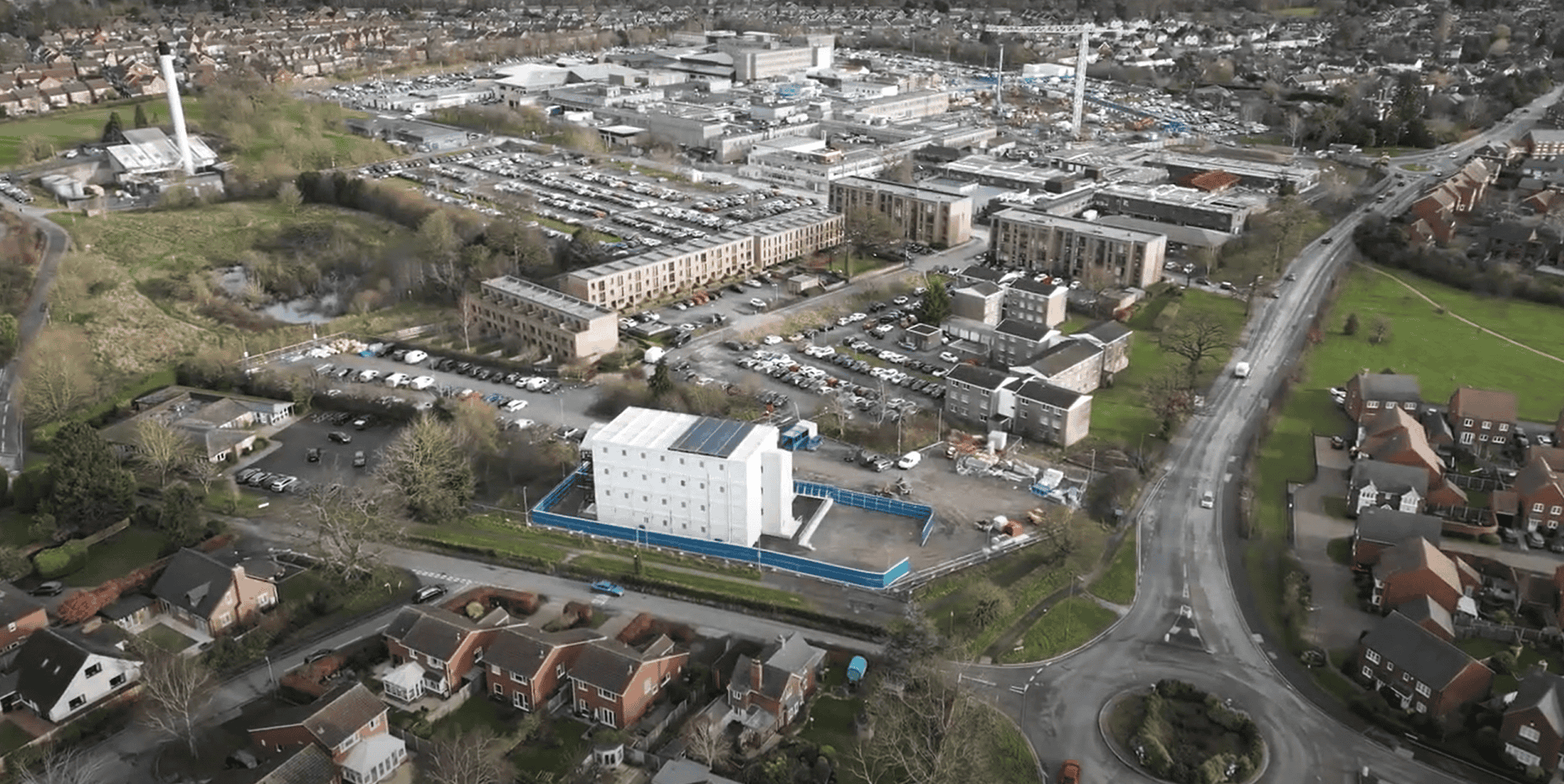

PET-CT scanning unit, Norfolk and Norwich University Hospital

Client

Alliance Medical

Project managers

Lee Wakemans Management

Programme

4 weeks on site

Installation

1 day

BUILDING SOLUTION

Permanent

CUSTOMER PERSPECTIVE

GARY WALTERS, PROPERTY WORKSTREAM LEAD, ALLIANCE MEDICAL

“The most important benefit of a modular solution is the reduced programme compared to site-based construction. If we can complete a PET-CT facility several months earlier, as with the Norwich project, we can deliver these much-needed diagnostic services to patients sooner.

Premier helped us to achieve this and provided value for money as well as the capabilities and expertise we required. The staff operating the new facility are very happy with it and it is helping us to offer an enhanced patient experience and pathway for the local cancer network community in Norfolk.”

DAVID CURZON, SENIOR PROJECT MANAGER, LEE WAKEMANS MANAGEMENT

“Modular buildings can be relocatable which makes the approach very suitable for fixed-term service contracts. These buildings could potentially be moved to another hospital when the contract for the site expires. Offsite construction also suits hospital sites very well because there is much less time on site than with traditional building methods – a big advantage. The foundations and drainage are put in place while the facility is manufactured offsite in the factory. Having the building operational at an earlier stage is much less disruptive for the host NHS trust and most importantly, gets the diagnostic services up and running for patients more quickly.

Premier performed well on this project and everyone is pleased with the building which is operating well. We look forward to working with their team on future schemes.”

BRIEF

A new, purpose-designed PET-CT scanning facility was required at Norfolk and Norwich University Hospital. Alliance Medical, one of Europe’s leading providers of imaging services, was awarded a national PET-CT contract by NHS England under the Wave 1 PET-CT procurement to deliver PET-CT scanning across 30 locations in England. A new modular unit was required to serve the local community in Norfolk.

PROJECT CHALLENGES

- This was a complex, fast-track project which involved engineering the building structure and floor system to meet the loadings of the scanner and the stringent specification for acoustic and floor response factors, whilst maximising work offsite at Premier’s factory.

- Access to the site was on a blue light ambulance route and close to the air ambulance helipad which required careful logistical planning and close monitoring with emergency services throughout the installation phase.

THE OFFSITE SOLUTION

The new facility was manufactured and fitted out at Premier’s offsite production centre and craned into position complete with the PET-CT scanner, doors, windows, partitions, glazed screens, and all mechanical and electrical services to reduce work on site to just four weeks. This approach significantly reduced the overall build programme.

Installation was completed on a Sunday to minimise disruption to the hospital.

The heaviest module containing the PET-CT scanner weighed 22 tonnes and required a 350-tonne crane for its safe installation.

THE FACILITY

The single-storey building accommodates a fully lead-lined scanning room, which is designed to provide a calming patient environment with illuminated landscapes on the ceiling and images along one of the internal walls. There is also a separate control room, and staff and patient support facilities.