When you think of a hospital building, what comes to mind? Bricks and mortar or modular construction?

As part of the Construction 2025 strategy, the government is advocating for increased use of offsite construction in the public sector. That’s because the real differences between offsite and traditional methods aren’t visual, but champion quick installation time, cost and carbon footprint of construction projects.

Modular healthcare buildings offer a range of benefits, including:

- Quality control: with all units built in a controlled factory environment

- Flexibility: with high adaptability and easy capacity expansion options

- Reduced disruption: hospitals can stay operational during renovations and patient contact with a live construction site is minimised

We’ve had the privilege of becoming trusted construction partners for hospital trusts up and down the UK, providing modular solutions that are high specification, compliant and always high quality.

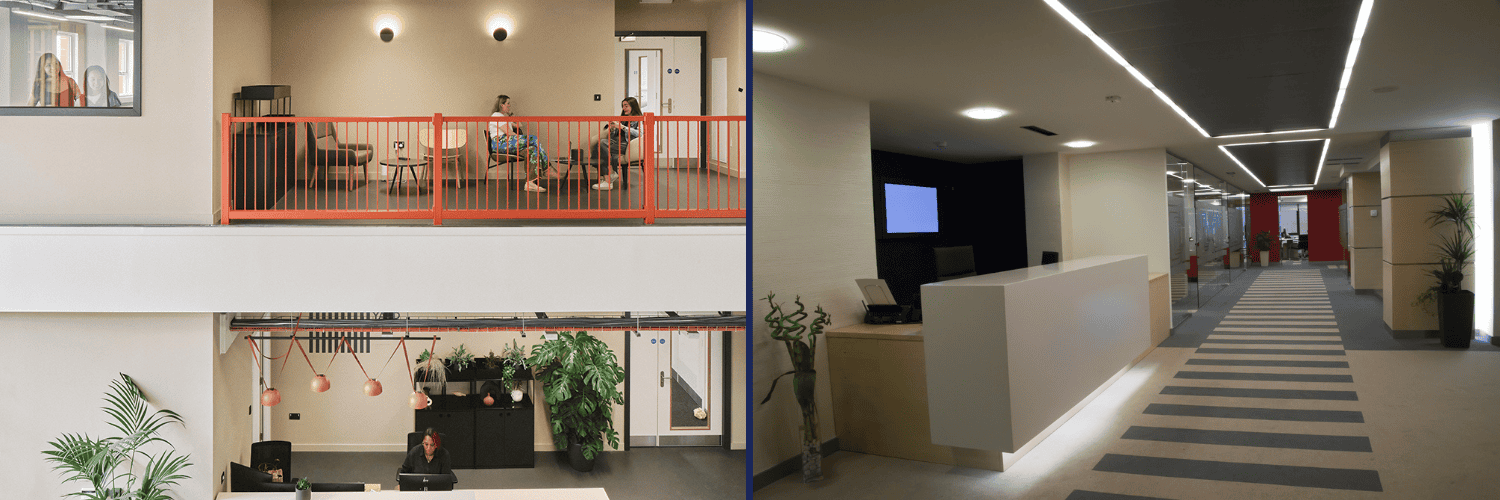

Do you think you could tell the difference between modular and traditional build? We think it’s time to put your eye for detail to the test. Using images from our own modular projects as well as ones built via traditional construction methods, we want to know if you can tell which is which.

Waiting Rooms

Clinic Room

Physiotherapy gym

Back-of-house-areas

The proof is in the building

How did you do in our spot the difference challenge? Whether you passed with flying colours or got stuck, one thing’s clear: modular construction is no longer the new kid on the block.

This fast, flexible, low carbon building method is quickly becoming the go-to option for healthcare projects of all sizes, blending seamlessly with current buildings and bringing serious advantages.

If you want to turn your modular healthcare building vision into reality, explore our permanent projects or get in touch today.